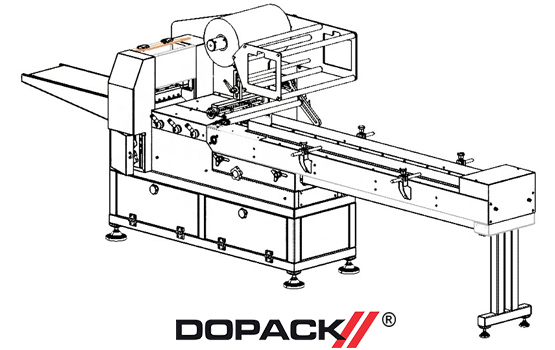

Dopack packaging machine is one of the leading Automatic Packing Machine manufacturers company is located at faridabad Haryana.our company keep developing Automatic Packing Machine Vertical and Horizontal packing Machine. We have Professional R&D Production Technical Support Team.

Dopack is Providing Entire Answer of various Packing need for Sugar pack, Tea, Coffee, Rice, Pulses, Grains, Spice powder, Chips, Snacks Flour powder, Detergent Powder, Pesticides, Pharmaceutical product etc.

Read more

Dopack participated packaging exhibition at north east June

2019

Dopack participated packaging exhibition at Bangalore April

2019

Dopack participated packaging exhibition at Colombo, Sri Lanka 2016.

Dopack participated “Khadya Khurak” at Ahmadabad, January 2016.

Dopack participated “Ahar” March 2016 at Pragati Maidan, New Delhi, India.

Dopack participated IndiaPack 2015 at Mumbai exhibition center in October 2015.

Dopack participated PackEx, September 2015 at Pragati Maidan, New Delhi, India.

Dopack participated AHAR 2015, Pragati Maidan, New Delhi, India.